Fulfilling High Mechanical and Optical Requirements

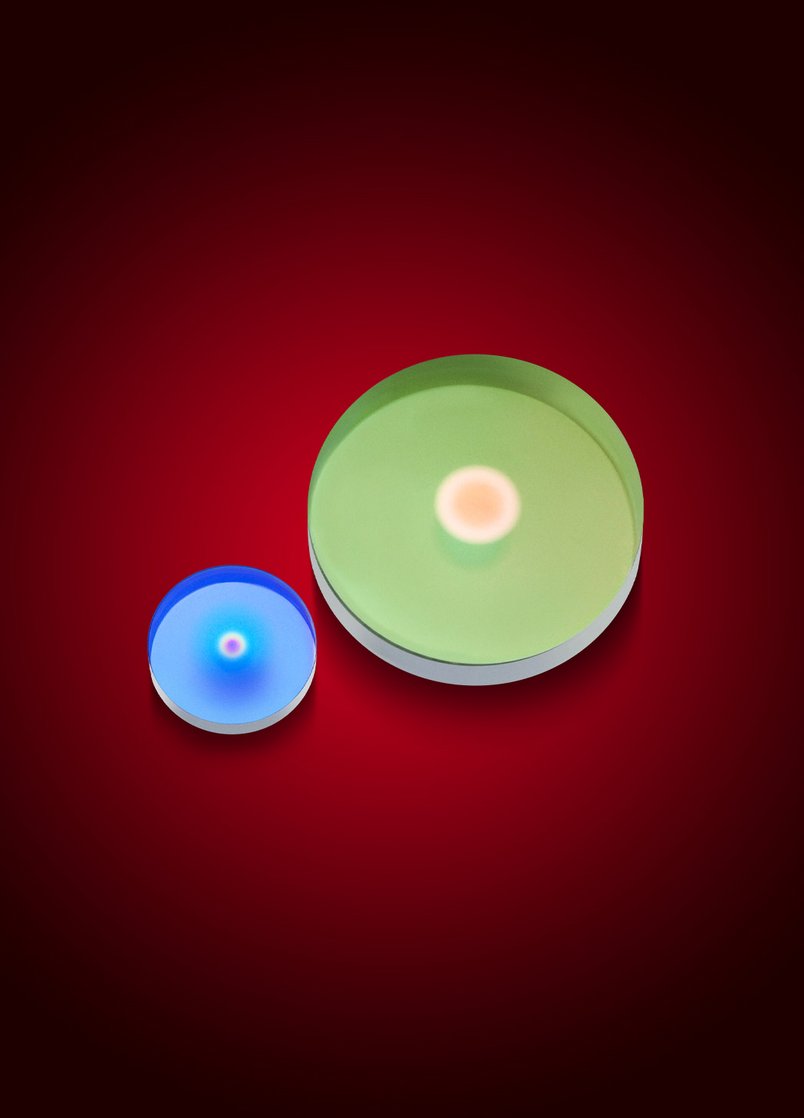

Scanning mirrors are used, for example, in laser material processing to move the laser beam quickly and flexibly across the workpiece. Fast scanning speeds, scanning rotation angles of 20-30°, and the power of the processing laser place high mechanical demands (the load resulting from movement forces) on the scanning mirrors. In addition, the scanning mirrors must have very good reflectivity across a wide angular range. For individual wavelengths from the range 248 nm to 3000 nm and wide scanner rotation angles of e.g. AOI=45°+/-15°, high reflections of typically R>99.5% must be achieved.

Customized adaptations: LASER COMPONENTS manufactures scanning mirrors made of quartz glass and silicon in various geometries. Shape and thickness can be customized. We would be happy to advise you personally and bring your custom design to life.

Contact

Benefits

- Wide range of shapes according to customer specifications

- Small quantities also possible

Features

- High reflectivity >99.5% across a wide angular range

- Reflective coatings across a wide range of wavelengths and angles

Click here

News & Events

Laser Optics