Laser Power Measurement

Laser Power monitoring is a direct and trivial application for any light detector. However there is one major difference between detectors used in power meters, and those used in power monitoring; detectors for power monitoring are not calibrated to a specific power level.

In power monitoring applications a detector is used to produce a feedback loop between the output of a laser and the electronics used to control it, producing a stabilized output power. Although this might sound simple, care has to be taken so a detector is not over saturated and the laser is within the detectors range of linearity. This is why beamsplitters or side reflections are used to only observe a small fraction of the laser light.

Build Laser Power Meters

with the right Detector

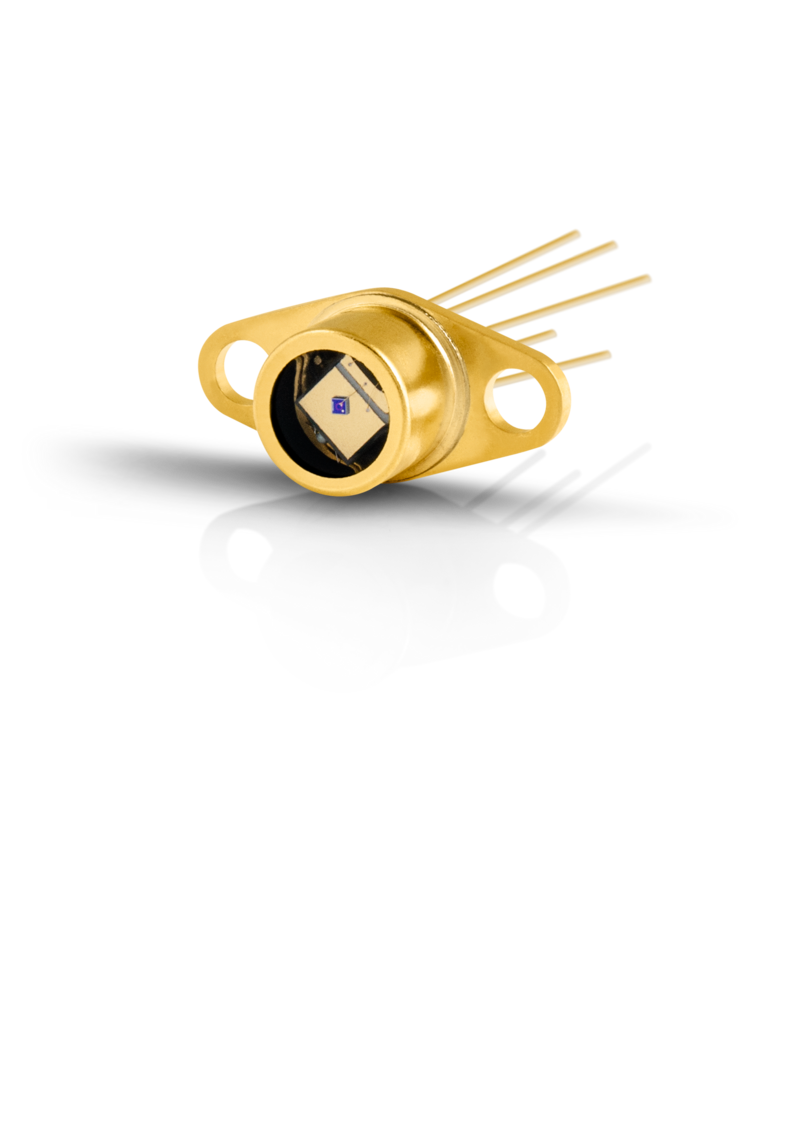

In most power monitoring applications the smallest photodiode will be more than enough to do the job; however, if you are looking to record the absolute power - even in arbitrary units - then larger area photodiodes are recommended.

Care also has to be taken to select the right spectral range, and effects of temperature are taken into account.

InGaAs or Silicon?

For lasers in the 900 – 1000 nm region silicon is still a popular choice of detector for power monitoring despite the fact that its responsivity is heavily temperature dependent in this spectral range.

InGaAs on the other hand has a far better temperature coefficient over this spectral band, with our IG17 series having a temperature coefficient of <0.1%/K. With the same coefficient becoming an entire order of magnitude less with our IG22 chemistry.

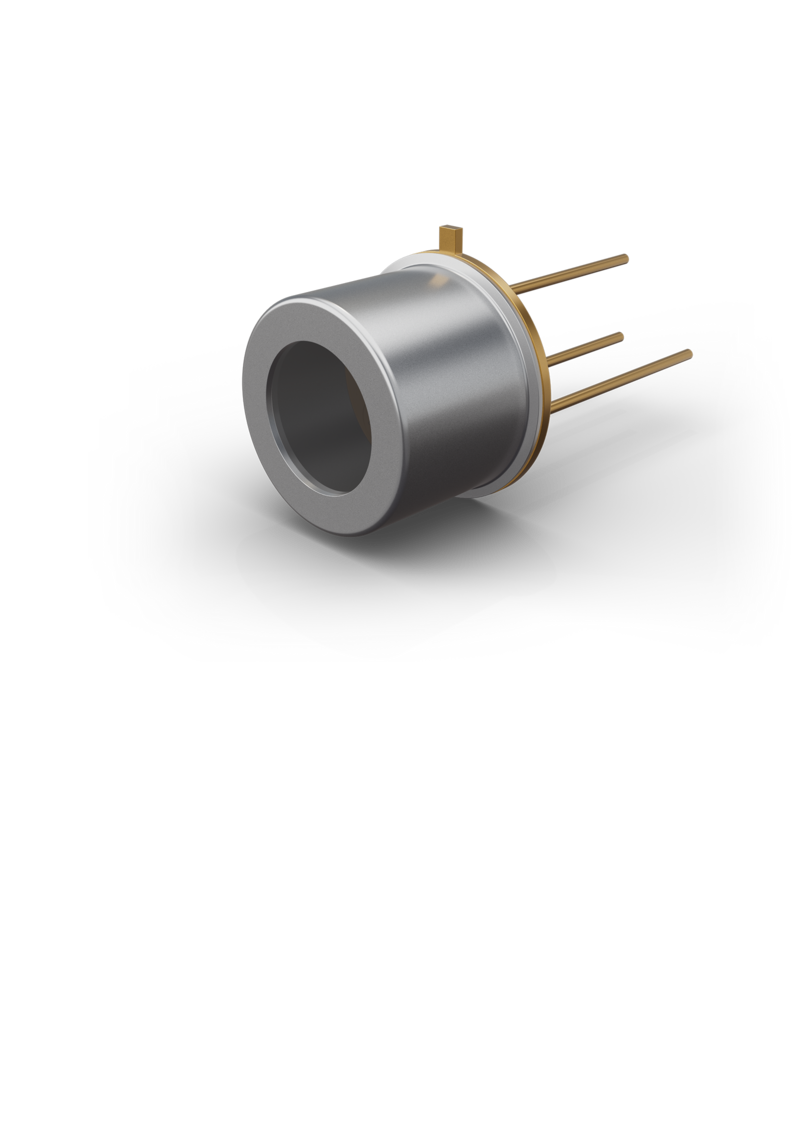

Pyroelectric

A high speed version with integrated OpAmp can be a sound option for applications up to a few kHz in cases where semiconductor based detectors are unsuitable.

Product Selection

for different needs

News

Read more